Machine tools and cutting

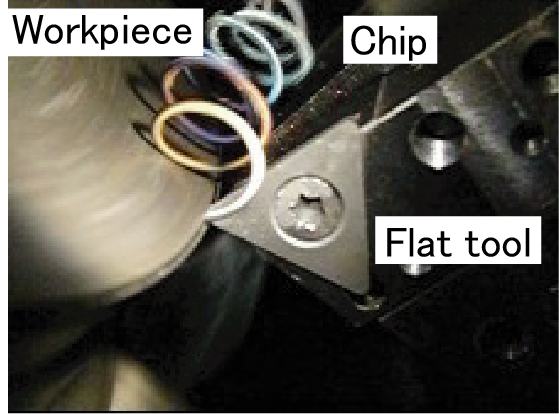

Analysis and suppression of chatter vibration in cutting process

Cutting is an essential manufacturing technology used in many factories. Intense vibration called chatter vibration sometimes occurs during cutting, which leads to a poor surface finish and decrease of tool life. To solve these problems, we are studying the basic mechanism of chatter vibration, developing accurate analysis models, and proposing effective methods to avoid or suppress chatter vibration in turning, milling and other cutting processes.

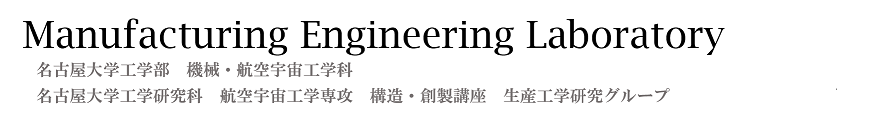

Proposal of chip-guided turning with grooved rake face for continuous chip disposal and chip

pulling

In the turning, highly-ductile chips generated in finishing ductile materials, such as low-carbon steel, heat-resistant alloys and aluminum alloys, are too ductile to be broken with the conventional chip breakers. Thus, it is difficult to solve the problem of chip jam as an extension of conventional concept. In this study, we propose chip-guided turning with grooved rake face for continuous chip disposal. The developed grooved tool can suppress the occurrence of curl and control the chip flow direction, so that the chips are navigated to a device for continuous chip disposal. This concept of continuous chip disposal can be combined easily with chip-pulling cutting, by which the machinability can be improved significantly by pulling the chip.

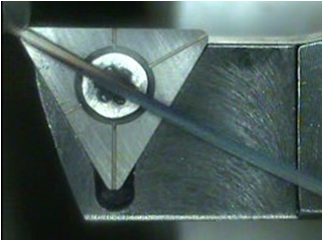

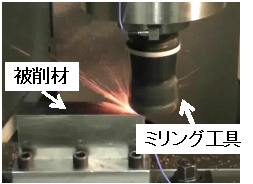

Highly efficient milling of superalloys with rotary/ceramic inserts

Nickel based superalloy is beginning to be widely used in aerospace industries. It is also well-known as a typical difficult-to-cut material due to its high cutting resistance, high temperature-strength and work hardening. Recently, rotary tools are being expected to attain better tool life as compared to the conventional tools. Our group has been dedicating to the joint research project on modeling of fundamental mechanics of cutting with rotary insert and development of new applications with some companies. High speed milling with ceramic inserts is also effective to attain high efficiency in superalloy machining with respect to the conventional machining with tungsten carbide tips. Although the tool life of the ceramic tip is extremely short, the tool damage mechanism is not fully-clarified. Our group is investigating the tool damage mechanism experimentally and analytically