試験装置 Experiment equipment

Bubbling fluidized bed reactor

A bubbling fluidized bed reactor with a 2-meter-high reaction tube has been newly installed. By supplying air or reactive gas from the bottom, the particle bed is fluidized to create a uniform reaction environment.

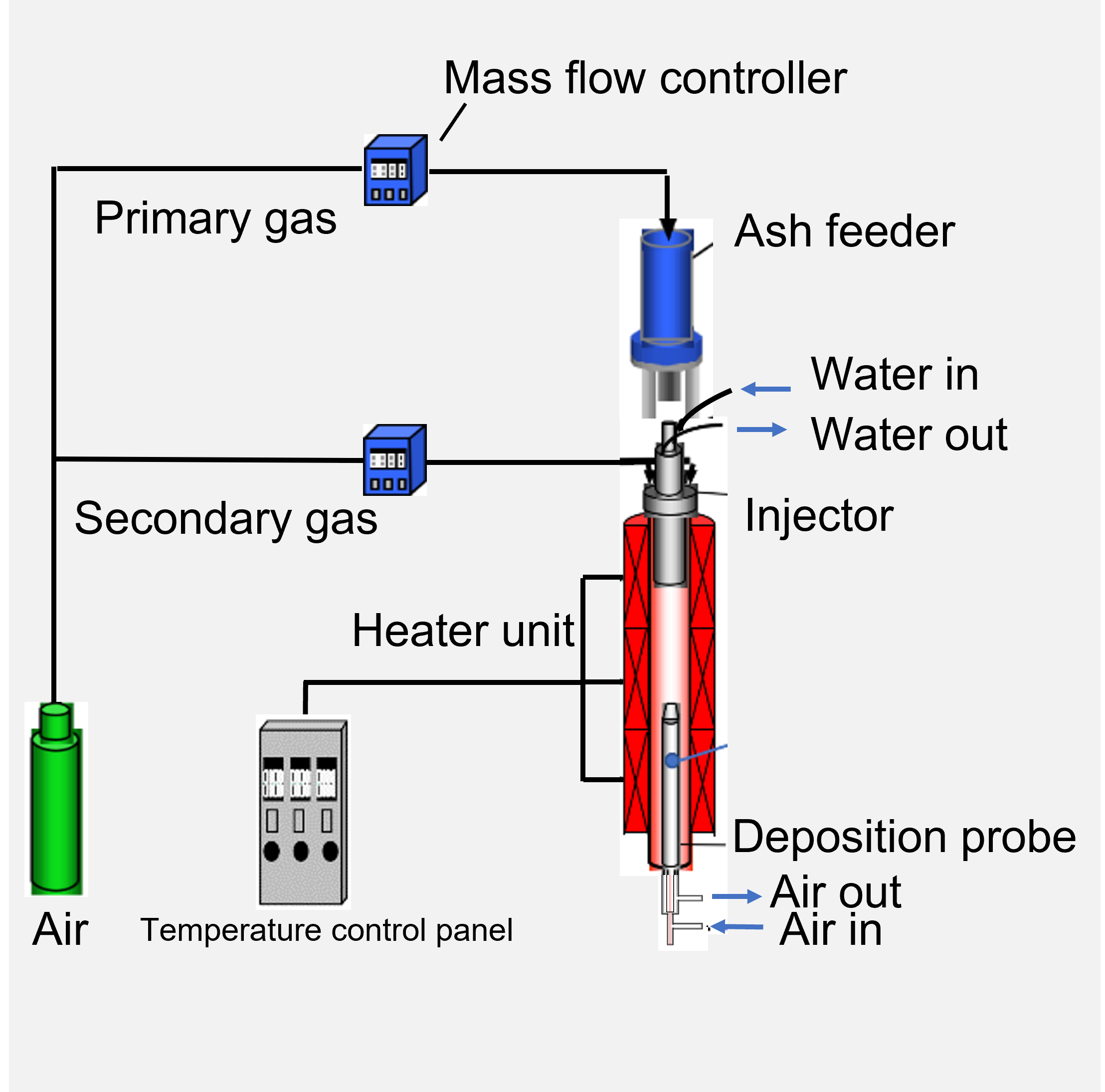

Drop tube furnace(DTF)

The DTF simulates spray combustion under conditions similar to commercial boiler. In our lab, is used to evaluate ash deposition and combustion characteristics.

Batch-type, vertical furnace

It is equipped with a vertically movable electric furnace which allow for rapid heating of samples to simulate isothermal combustion and gasification processes.

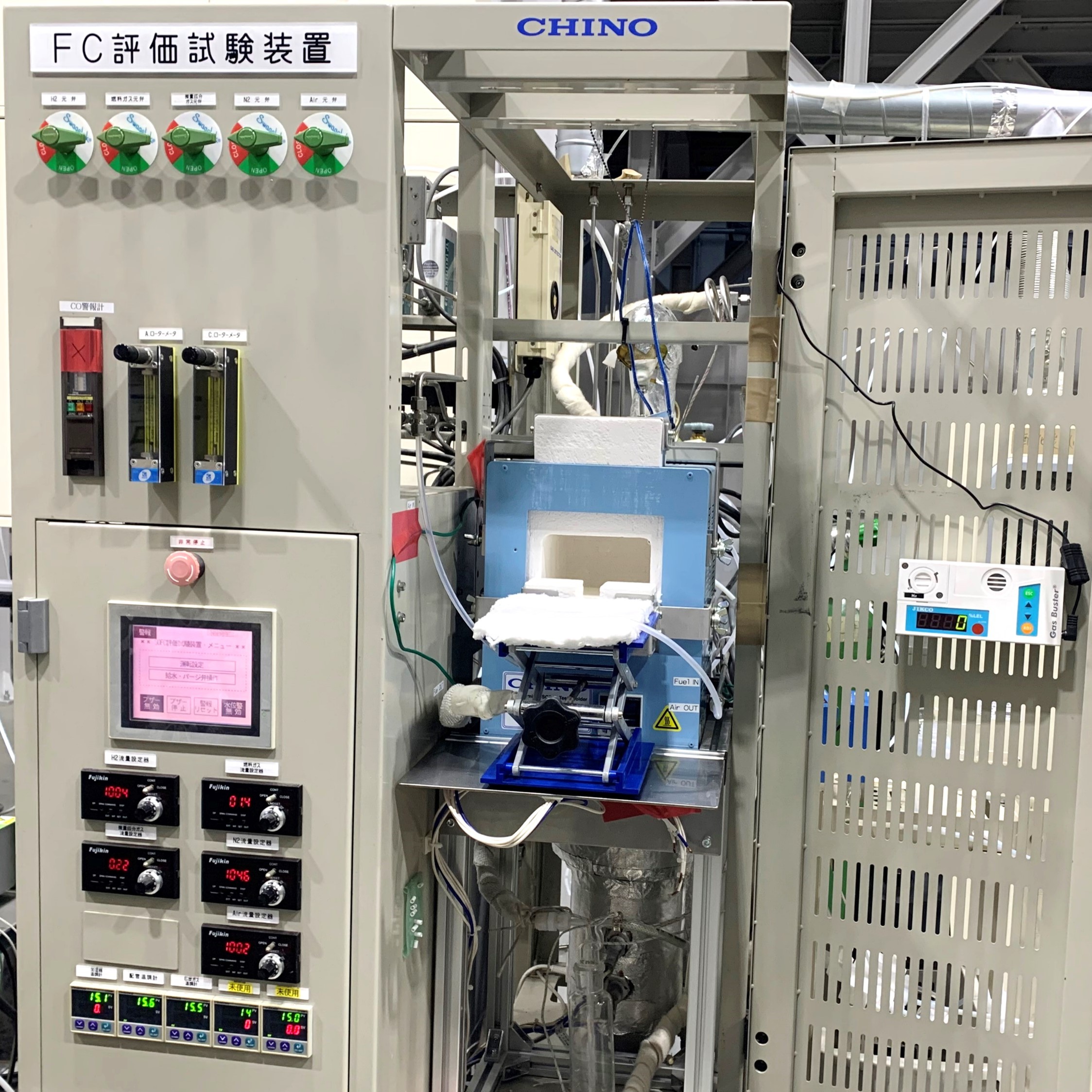

SOFC evaluation test equipment

A button-shaped solid oxide fuel cell is placed in the ceramic holder and utilized for performance evaluation under biomass gasification gas conditions.

マッフル炉

The furnace is designed to prevent direct heating of the sample by the heater. Instead, indirect heating is achieved using a partition, such as an alumina ceramic plate. This setup is used for ashing and pyrolysis experiments.

NOx reduction equipment

A novel NOx reduction device featuring a calcium ferrite-based catalyst and capable of continuous biomass char feeding is currently under development. Stay tuned!

分析装置 Analytical equipment

Scanning electron microscope (SEM)

The nanostructure of the sample is observed at the nanometer scale. Coupled with EDX, qualitative and quantitative element analysis is also possible.

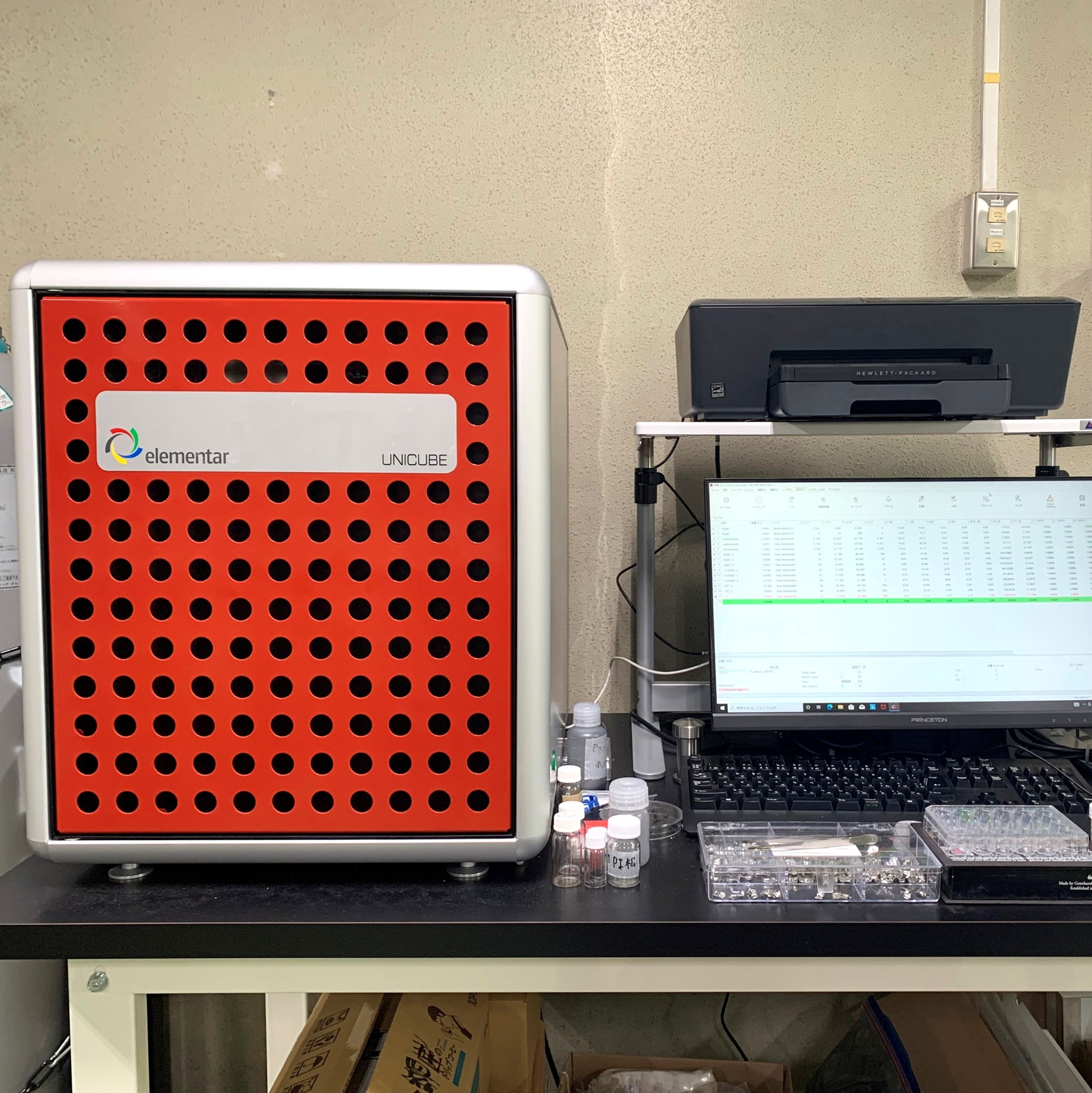

Organic Elemental analyzer

It performs elemental analysis (C,H,N,S) of organic compounds using the combustion method. It is extensively applied in various materials, including coal, biomass, and waste.

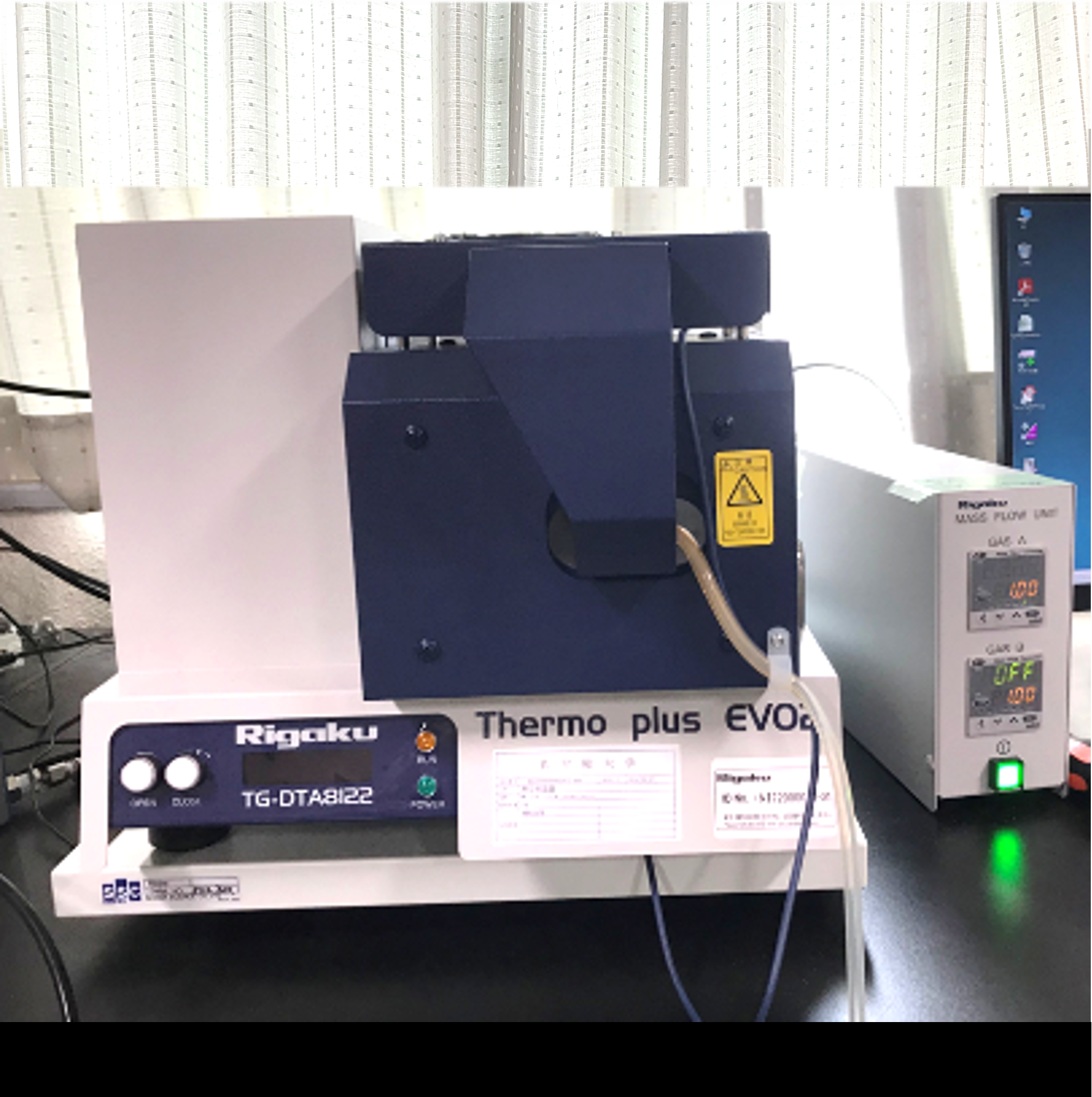

TG-DTA

The use of a horizontal differential system minimizes the effect of gas flow, allowing for simultaneous differential thermal and thermogravimetric measurements.

Micro gas chromatography (Micro-GC)

It is used for analyzing exhaust gas composition. A variety of models are available in our lab to accommodate different types of exhaust gases.

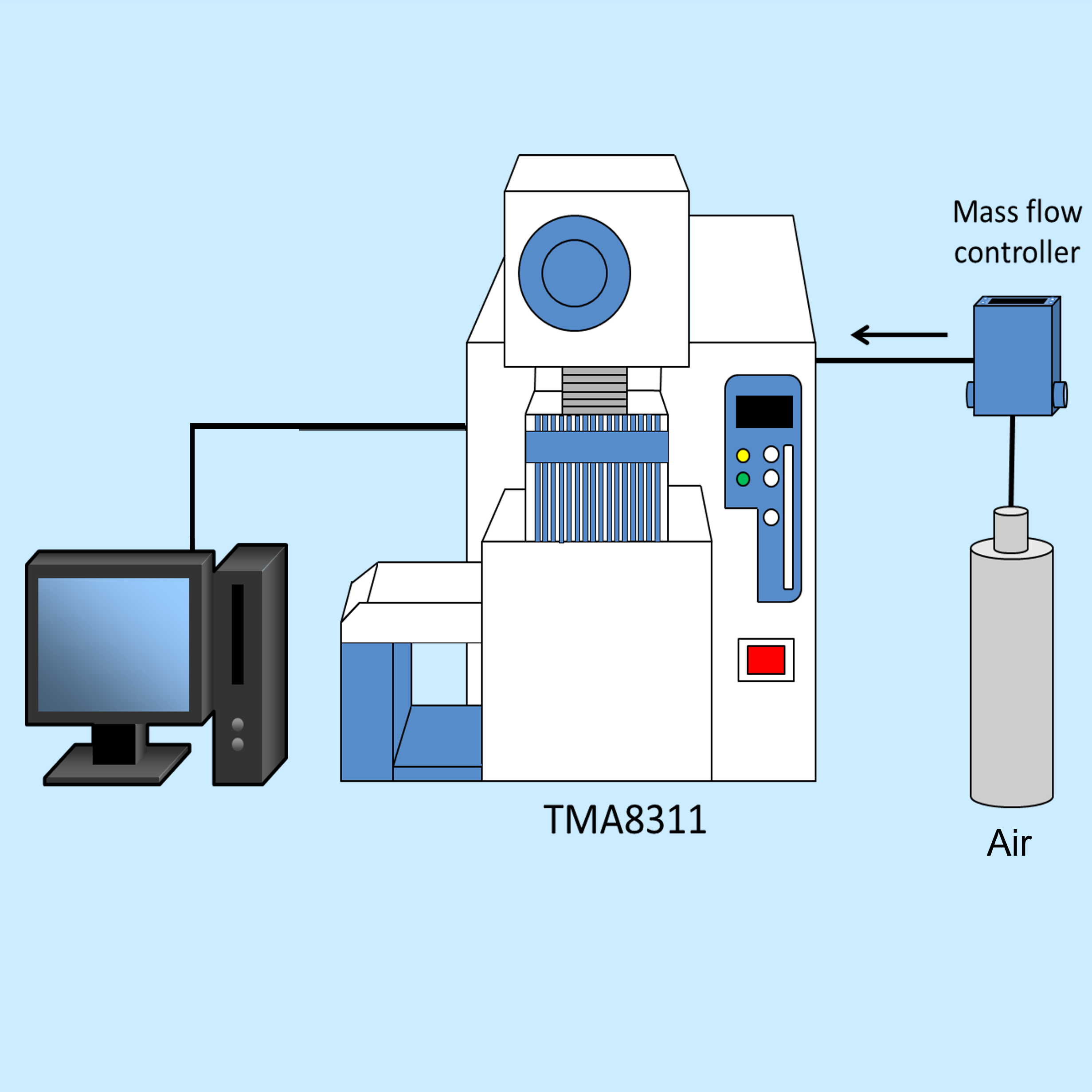

Thermomechanical analyzer(TMA)

It is capable of detecting shrinkage displacement under load during heating process.

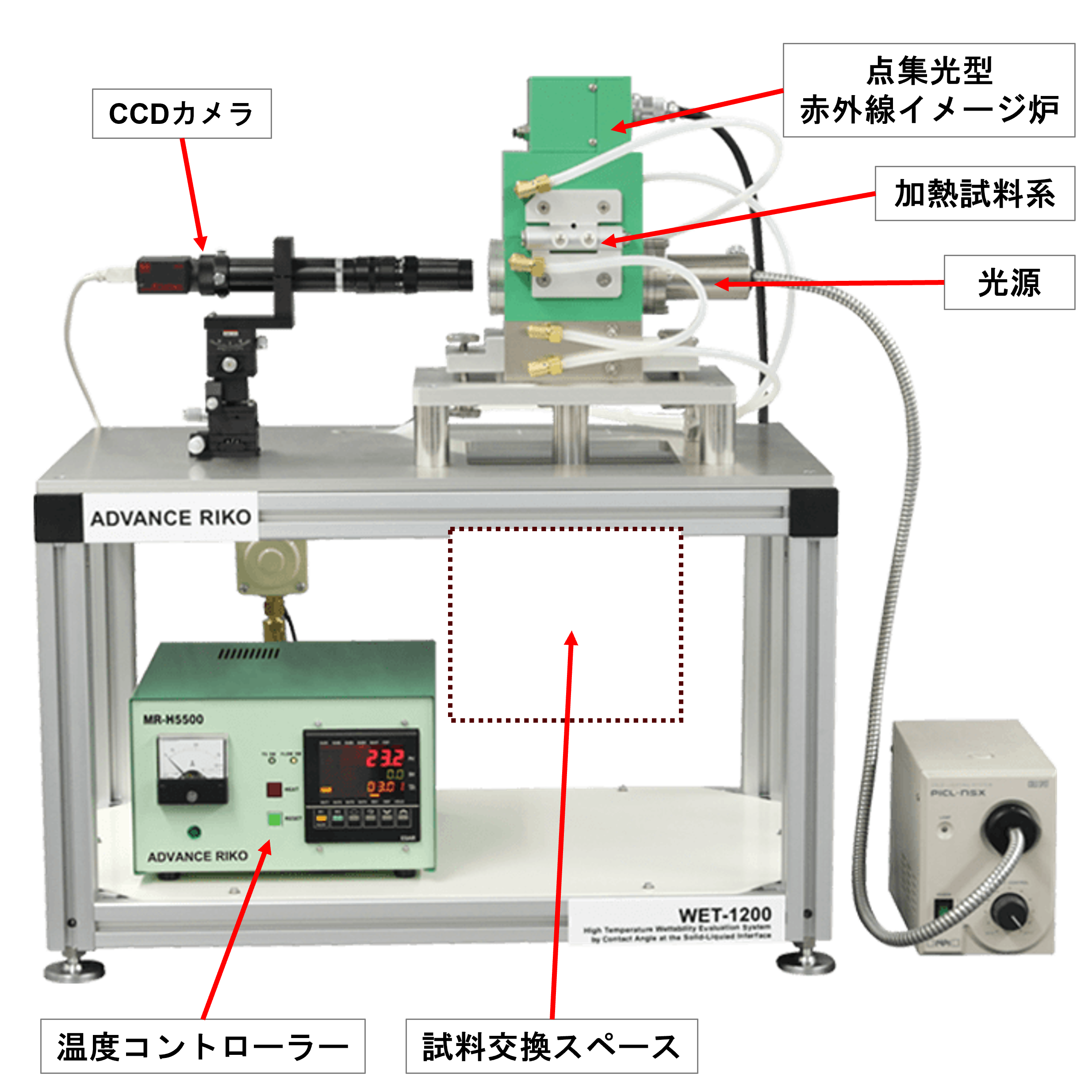

Contact angle mesurement equipment

This device measures the wettability between substrate and sample. Equipped with a CCD camera, it enables quantitative evaluation of time-dependent changes in the contact angle.

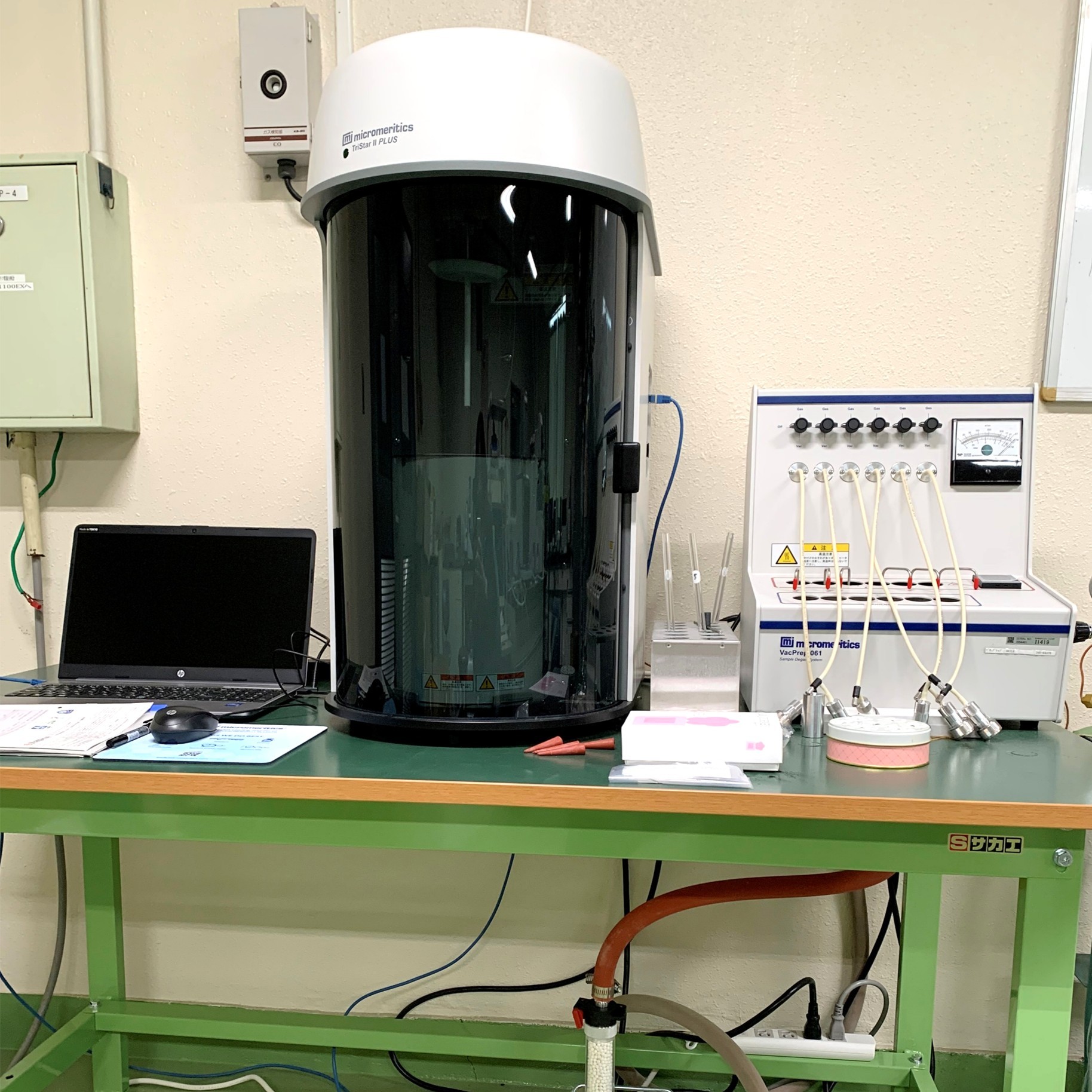

Surface area and porosimetry analyzer

This device measures specific surface area and pore size distribution using the volumetric method based on gas adsorption.

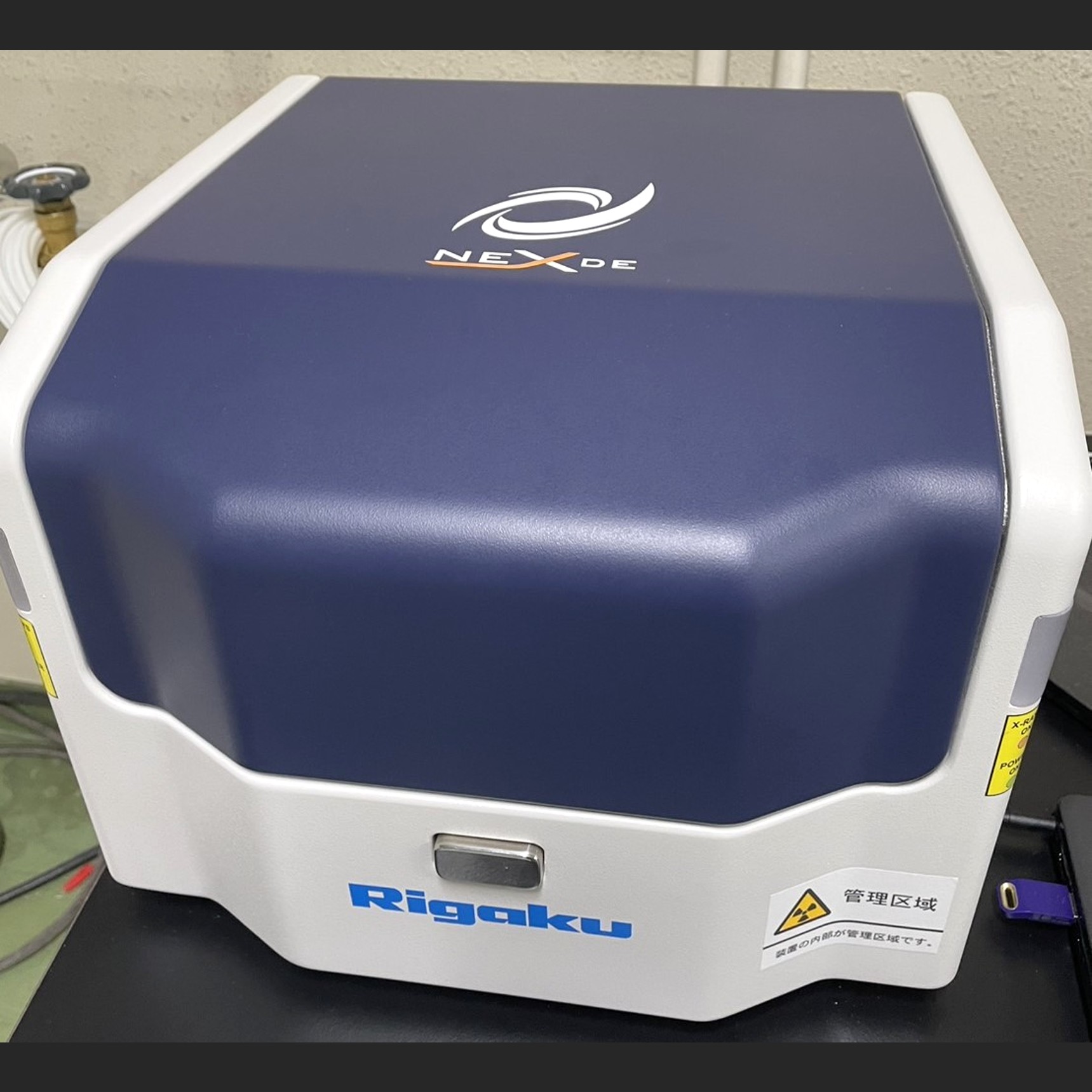

X-ray fluorescence spectrometer (XRF)

Without any pretreatment, solid samples can be directly analyzed for trace elements in a non-destructive way.